Air Bearing | Instruction

Instruction

Read all the operating instructions below to prevent malfunctions caused by mounting, or air supply.

Operating Environment

Temperature : 18~28℃

Humidity : 70% or lower.

Before opening the package,leave the product at room temperature to prevent condensation.

Supply air

Use clean dry air with the following specifications.

Working pressure : 490 ~ 690 kpa ( 5~7 kgf/cm2 )

Atmospheric dew point : Less than -15℃

Final filter mesh : 0.01µm Micro Mist Filter with automatic drain mechanism (Removes oil mist)

* Never operate without clean and dry air, all most of the malfunctions of air bearings are caused by insufficient supply air.

* Membrane dryers or Refrigeration dryers are commercially available from manufacturers of air equipment.

* Confirm the discharge capacity flow rate of the supply air source is greater than or equal to twice the air consumption of each air bearings.

Precautions for Operation

First of all, to remove any dust in the piping system.

Next, blow clean dry air into air bearings for at more than one hour.

Release the rotary lock only under air supplying.

Don't rotate the air bearings when air is not being supplied.

Inter lock

To avoid potential problems air is down by more than 100 kpa from normal working pressure, install a pressure switch on the air piping an interlock for switching off the power.

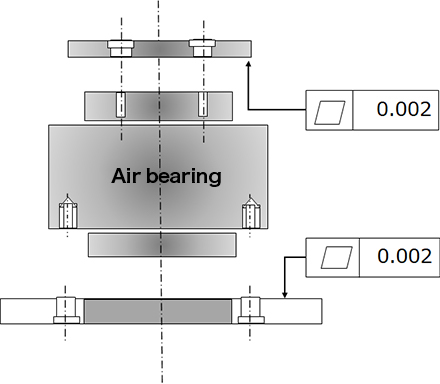

Mounting base and plate specifications

Coefficient of thermal expansion : Less than 11 × 10-6 / deg-C Flatness : Less than 2µm

Since the bearing clearance of air bearings is very small, mounting bases and plates with poor flatness accuracy will cause distortion and cause trouble.

Also, the material to be mounted should have the same coefficient of thermal expansion as the air bearing. The bimetal effect causes problems due to distortion.

Clamping procedure

Minimize clamping distortion by gradually increasing the torque in several steps.

Work the clamping steps under air supply.

| Screw size→ Clamping torque↓ |

M3 | M4 | M5 | M6 | M8 | M10 |

|---|---|---|---|---|---|---|

| MAX (N,cm) | 200 | 390 | 780 | 1180 | 2450 | 2940 |

| MAX (kgf,cm) | 20 | 40 | 80 | 120 | 250 | 300 |

Dynamic balance

Dynamic balance of the rotation axis should be adjusted based on applications, and the frequency of use.

In high-speed rotation use, take risk prevention measured by installing a cover.

Allowable impact force in centering jigs

Under air supplying : Less than 1/6 of rigidity. (Normal Radial and Axial Load)

No impact force is allowed under no air supplying.

When equipment using air bearings are stopped for a long period of time

Even if the equipment using air bearings is not used for a long period of time, it is recommended not to stop the air supply to prevent the ingress of any liquid such as water, oil, organic solvent or moisture.